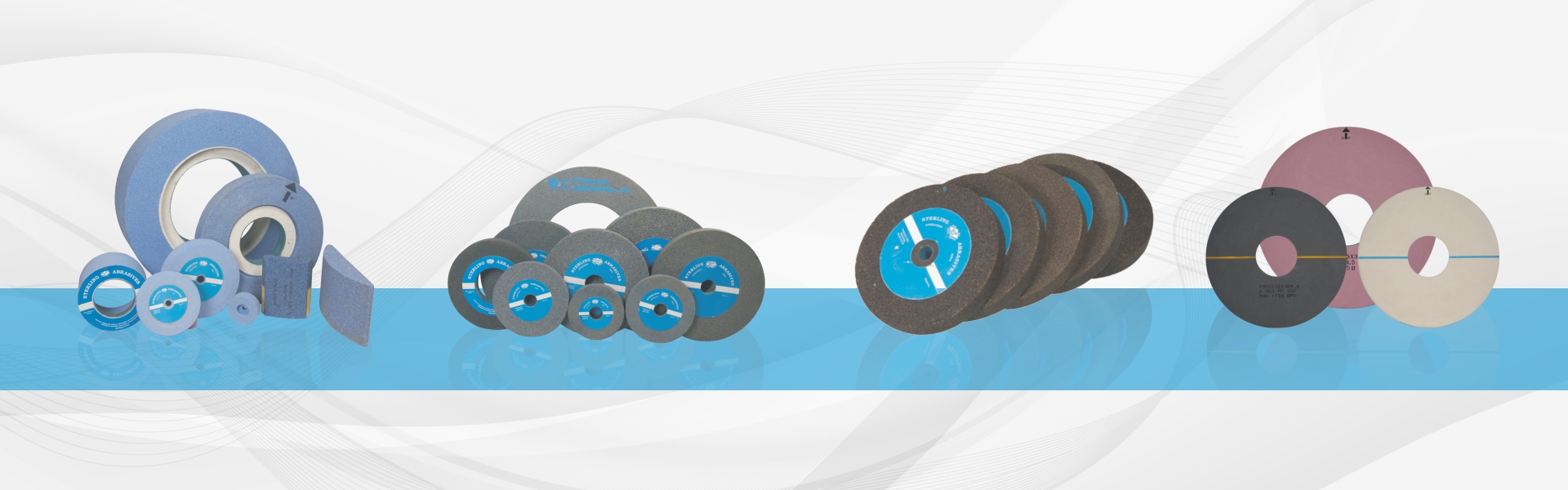

Crank Shaft Grinding Wheels

- Crank Shaft grinding is the cylindrical grinding of the crank pin or bearing by plunge form method. Normal speed of operation: 33 to 45 MPS.

- Sterling’s crank shaft wheels grind freely, generate minimum heat and at the same Time maintain its form and size for a sufficient length of time. It is used by all types of crank shaft manufacturers and regrinding industry.

- Suitable for machines like Landis, Rial, Norton, Naxos Union, Newall, Churchill, Parishudh etc.

Specification

Warning: Invalid argument supplied for foreach() in /web/qlc/sterlingabrasives.com/htdocs/wp-includes/shortcodes.php on line 591

| Material | Grading | ||

|---|---|---|---|

| Forged Steel-soft (Roughing) | A463 N5 VC10 | – | – |

| Forged Steel-hard (Roughing) | A463 L5 VC10 | DA46-2 L7 VSC | FSA 463 L5 VSC |

| Forged Steel – hard (Finishing) | DA80-1 J7 VSC | – | – |

| Cast Iron (Roughing) | DA46 L5 VSC | – | – |

| Cast Iron (Finishing) | DA80 K7 VSC | – | – |

| Re-grinding | A463 L5 VC11 | – | – |

| Spheroidal Graphite [SG] Iron | DA463 L5 VC11 | – | – |

| Carburlzing & heat treated Steel | A463 L5 VC10 | A543 J5 VSC | – |

Warning: Invalid argument supplied for foreach() in /web/qlc/sterlingabrasives.com/htdocs/wp-includes/shortcodes.php on line 591

| Abrasive | Diameter | Thickness | Grit | Hardness | Structure |

|---|---|---|---|---|---|

| A, DA | 300 – 1220 | 20 – 100 | 46 – 80 | J – O | 5 – 8 |

Warning: Invalid argument supplied for foreach() in /web/qlc/sterlingabrasives.com/htdocs/wp-includes/shortcodes.php on line 591

| 660.4 X 22.23 X 152.4 | 812 X 25.4 X 203.2 |

| 660.4 X 22.23/32/33/40 X 203.2 | 900 X 38.1 X 304.8 |

| 711.2 X 25/32/38 X 203.2 | 914 X 25.4 X 304.8 |

| 762 X 25 X 203.2 | 1015 X 32.5 X 304.8 |