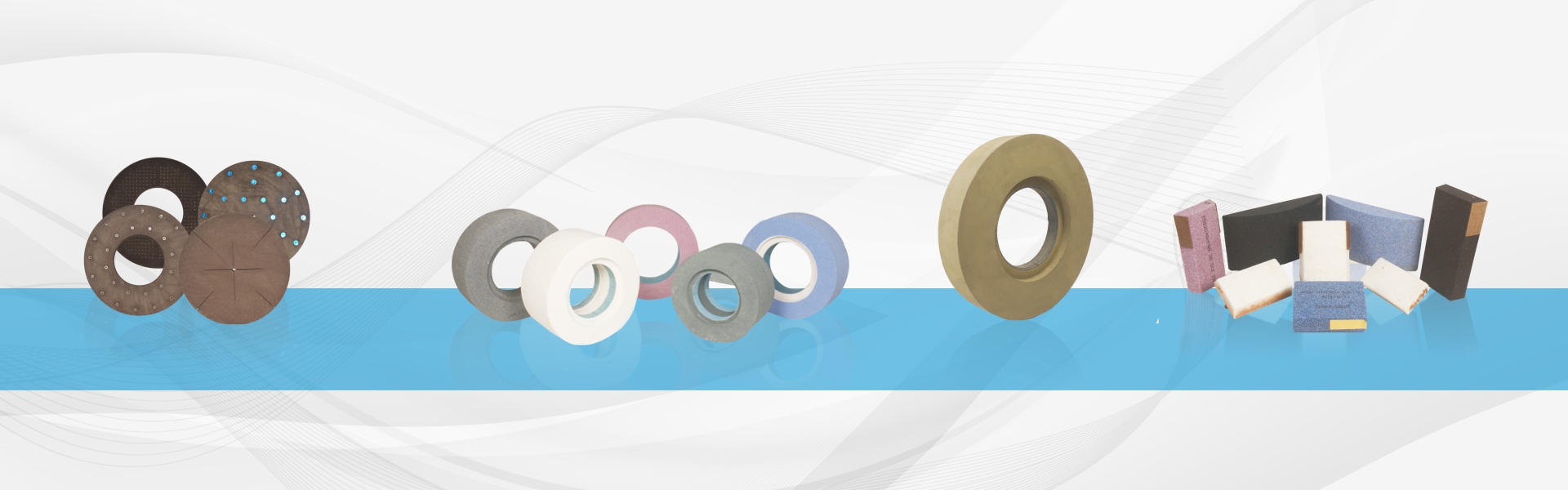

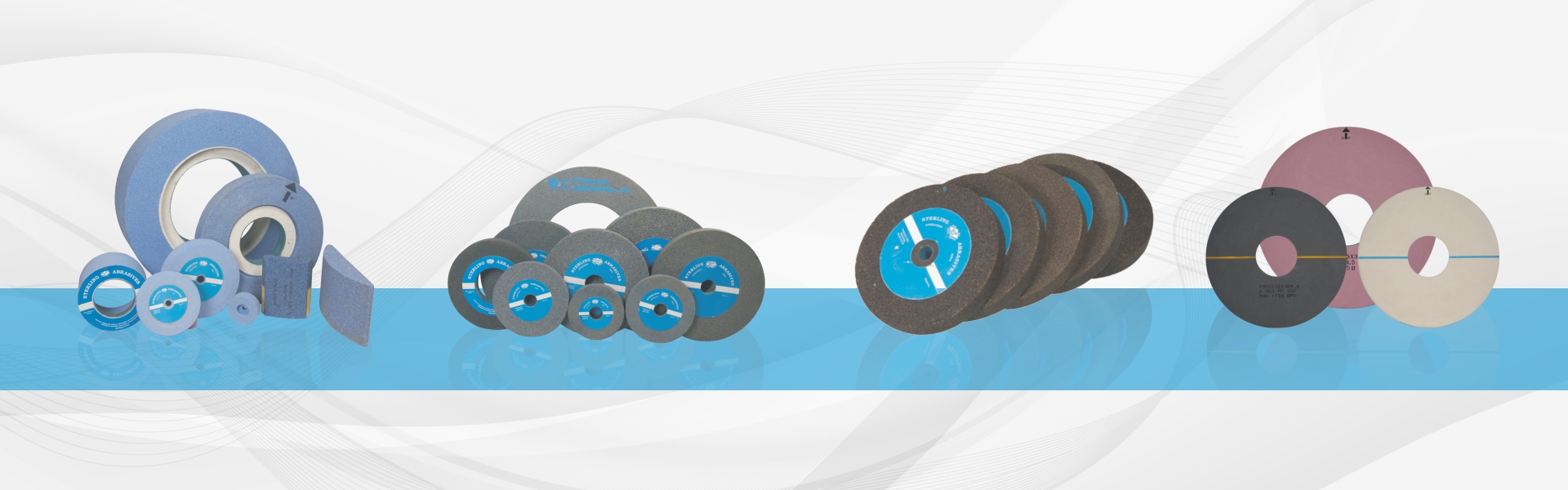

Cylindrical Grinding Wheels

- Cylindrical Grinding is the grinding of the outside diameter of components revolving between centres or while held in a chuck. Cylindrically ground parts are more accurate in size with better finish than those turned on lathes.

- Sterling’s versatile range of cylindrical grinding wheels are used tor a variety of grinding operations that require size generation, fine surface finish and fast stock removal.

- Special wheels are available for multiple diameters and shoulder grinding with the side or the wheel where wheel gradings are adjusted for plunge grinding without any traverse.

- Suitable for machines like Landis, Kirloskar Landis, Churchill, Newall, WMW, Praga, HMT, Riat, Toshiba, Norton, Parishudh etc.

Specification

Warning: Invalid argument supplied for foreach() in /web/qlc/sterlingabrasives.com/htdocs/wp-includes/shortcodes.php on line 591

| Material | Grading |

|---|---|

| Cast Iron | C46 K5 V4 |

| Steel – Solt | A463 L5 VC10 |

| Steel – Hardened | A463 K5 VC10 |

| Steel – High Speed | AA46/54 K5 VC8 |

| Stainless Steel | C463 N5 V4 |

| Tungsten Carbide | GC60 K5 V4 |

| General Purpose | A463 L5 VC10 |

Warning: Invalid argument supplied for foreach() in /web/qlc/sterlingabrasives.com/htdocs/wp-includes/shortcodes.php on line 591

| Abrasive | Diameter | Thickness | Grit | Hardness | Structure |

|---|---|---|---|---|---|

| A, DA | 300 – 1220 | 6 – 150 | 36 – 120 | I – O | 3 – 6 |

| AA | 300 – 1220 | 6 – 150 | 36 – 180 | I – N | 4 – 5 |

| C | 300 – 1220 | 6 – 150 | 36 – 180 | I – N | 4 – 5 |

| GC | 300 – 1220 | 6 – 150 | 46 – 220 | I – N | 4 – 5 |

Warning: Invalid argument supplied for foreach() in /web/qlc/sterlingabrasives.com/htdocs/wp-includes/shortcodes.php on line 591

| 300 X 25 X 127 | 350 X 40 X 127 | 500 X 50 X 254 |

| 300 X 40 X 127 | 400 X 40 X 127 | 450 X 65 X 254 |

| 350 X 25 X 127 | 400 X 40 X 127 | – |