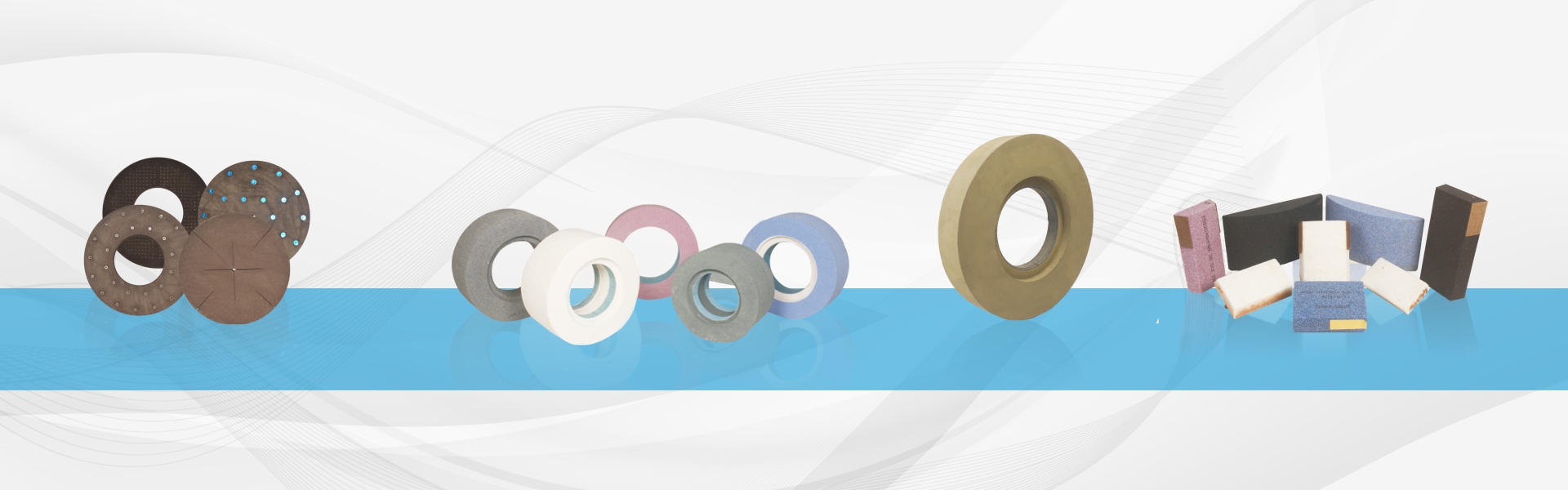

Gear Grinding Wheels

Gear grinding is a finishing process to remove considerable amount of metal after heat. Treatment operation to obtain a predetermined quality. Gear grinding is done to meet the exact requirement of form, dimension and surface texture. Gear grinding gives a very high degree of dimensional accuracy.

Methods of Gear grinding

- Generating type method – In this process, the wheel progressively approaches the root or the gear from the tip or the gear tooth. Suitable for Machines like Maag & Hoffler.

- Form / Profile grinding – In this process the Wheel is In constant touch with the work piece.

Suitable for Machines like Reishauer & Csepel.

Specification

Warning: Invalid argument supplied for foreach() in /web/qlc/sterlingabrasives.com/htdocs/wp-includes/shortcodes.php on line 591

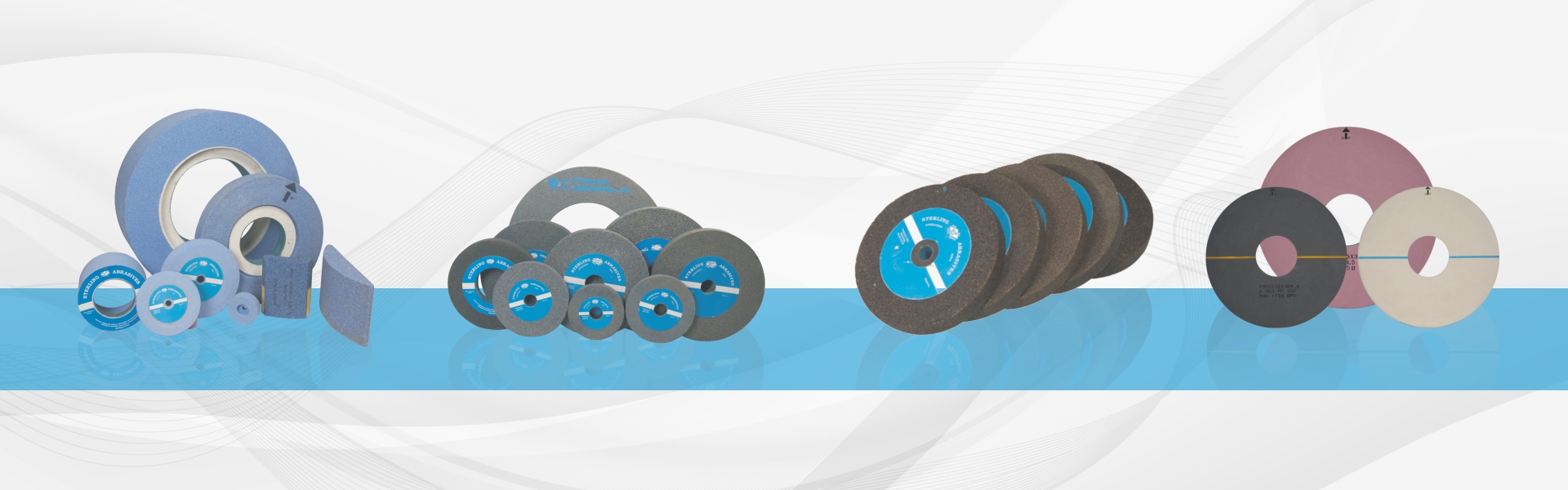

| Size | Conventional Grading | Ceramic (CG) Grading |

|---|---|---|

| 280 X 33 X 90 | AA46 I5 V15 | 3CG46 I5 VC8 |

| 307 X 38 X 127 | AA36 I5 Vl8N | 3CG36 I8 VC8 |

| 350 X 25 X 127 | PAA46 H8 VP7 | 3CG46 H8 VSC |

| 350 X 25 X 127 | AA46 I16 V18N | 2CG46 I10 VSC |

| 350 X 84 X 160 | AA100 K6 VSC | 3CG 100 K6 VSC |

| 400 X 35 X 127 | PAA46 I10 VP7 | 3CG46 I10 VP7 |

| 450 X 29 X 127 | PAA46 I7 VP7 | 3CG46 I8 VSC |

| 450 X 104 X 160 | PA100 K5 V1 8N | 3CG100 K6 VSC |

Warning: Invalid argument supplied for foreach() in /web/qlc/sterlingabrasives.com/htdocs/wp-includes/shortcodes.php on line 591

| Abrasive | Diameter | Thickness | Grit | Hardness | Structure |

|---|---|---|---|---|---|

| PAA, M, CG | 280 – 500 | 25 – 104 | 36 – 220 | G – K | 5 – 7 – 8 – 16 |